In today’s rapidly advancing industrial landscape, efficiency and precision are not just advantages—they are necessities. Modern manufacturing and engineering sectors demand tools that can deliver consistent, high-quality results while maintaining safety, cost-effectiveness, and reliability. Among the many industrial innovations that have emerged to meet these demands, one model has gained particular attention for its superior performance and adaptability: the TEK-102 industrial machine.

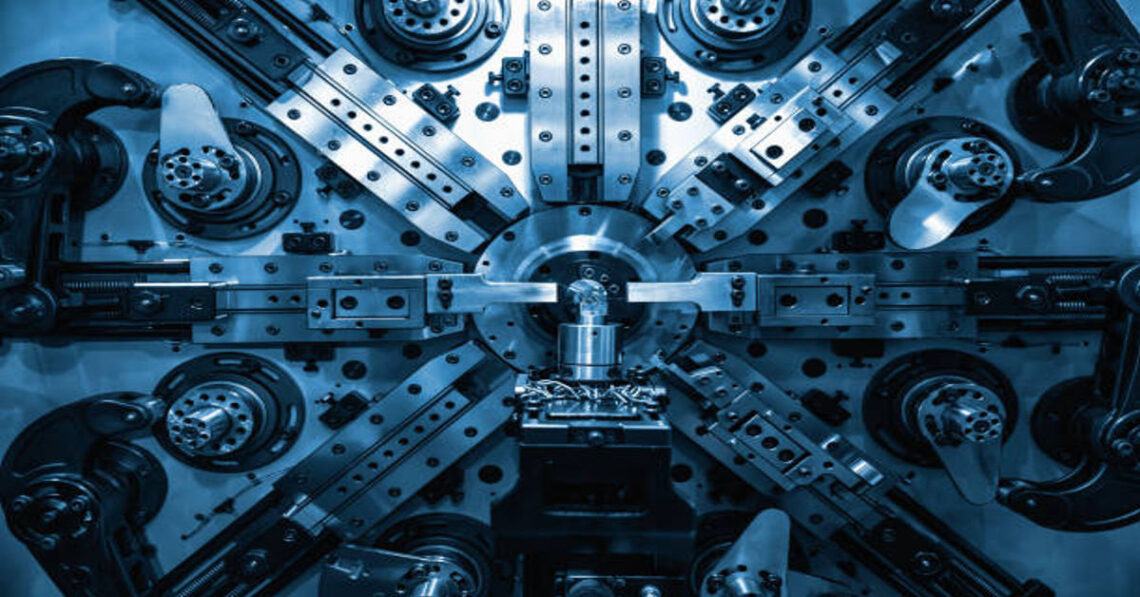

The TEK-102 represents a refined fusion of engineering excellence and technological advancement. Designed for diverse applications across manufacturing, metalworking, fabrication, and process engineering, this machine exemplifies what modern industry expects—high torque, energy efficiency, advanced control systems, and long-term operational durability. Unlike traditional industrial tools that often prioritize either power or precision, the TEK-102 strikes an optimal balance between both, making it a cornerstone in smart manufacturing systems.

This comprehensive article explores the TEK-102’s features, design principles, applications, operation, maintenance, safety protocols, advantages, and comparisons with similar tools. Whether you are an engineer, technician, or industrial decision-maker, this guide provides the insight needed to understand why the TEK-102 stands out as a symbol of modern industrial capability.

1. Overview of the TEK-102 Industrial Machine

The TEK-102 is a multi-purpose, high-performance industrial tool engineered to perform with remarkable accuracy and stability under intensive working conditions. It can be configured for multiple industrial processes such as cutting, drilling, shaping, or assembling, depending on the sector in which it is used. Its core design philosophy revolves around adaptability, ensuring it can serve a wide range of industries—from heavy metal fabrication to precision component manufacturing.

The primary focus of the TEK-102’s design is consistent output with minimal human intervention, made possible through an integrated digital control system and automated feedback sensors. This makes it particularly suitable for use in Industry 4.0 environments, where automation, data exchange, and real-time monitoring define productivity.

| Key Specification | Details |

|---|---|

| Model Name | TEK-102 |

| Type | Industrial Multi-function Machine |

| Power Source | Electric (3-phase) |

| Motor Capacity | 5.5 – 7.5 kW (depending on configuration) |

| Control Interface | Digital touch controller with programmable settings |

| Speed Range | Variable, up to 2500 RPM |

| Operating Voltage | 380 – 415 V |

| Application | Fabrication, assembly, cutting, or machining |

| Build Material | High-grade steel frame with vibration damping |

| Cooling System | Integrated air and oil cooling system |

2. Design and Construction

The engineering integrity of the TEK-102 begins with its structural framework. Built from reinforced industrial-grade steel, the body ensures long-lasting rigidity and stability. The frame minimizes vibration, which directly contributes to accuracy in applications that require tight tolerances.

The machine bed and support system are precisely aligned using laser calibration during production, ensuring operational stability even under continuous high-speed loads. The design also incorporates noise reduction technology that keeps operational sound levels low, improving workplace comfort and safety.

Main Construction Features

- Precision Bearings: Reduce friction and enhance smooth motion.

- Anti-Vibration Mounts: Maintain tool stability during prolonged use.

- Smart Cooling Channels: Prevent overheating by distributing thermal load evenly.

- Modular Attachments: Enable quick reconfiguration for different industrial tasks.

- Dust and Particle Shields: Protect internal components from contamination in harsh environments.

The TEK-102’s compact yet powerful design allows it to fit efficiently into both small workshops and large industrial lines, adapting to the space and production volume required.

3. Operating Mechanism

The operational efficiency of the TEK-102 comes from its dual-mode control system, which offers both manual and automatic operation. In manual mode, operators have direct control over speed, torque, and positioning. In automatic mode, pre-programmed parameters guide the process through sensors and feedback systems.

Core Working Principle

At its heart, the TEK-102 relies on an electromechanical drive system powered by a three-phase induction motor. The motor shaft transmits torque through a precision gearbox, converting electrical energy into mechanical output. Sensors continuously monitor speed, load, and temperature, feeding data into the control interface.

The digital controller allows operators to adjust performance based on the type of material or operation. Through built-in algorithms, it prevents overloading and maintains optimal torque distribution. This ensures smoother operation, reduced component wear, and improved energy efficiency.

4. Key Features and Technologies

What distinguishes the TEK-102 from other industrial machines is its integration of smart technologies that increase precision, durability, and energy savings.

| Feature | Description |

|---|---|

| Digital Control Interface | Allows customization of speed, torque, and operation time through a user-friendly touchscreen. |

| Auto Calibration System | Automatically adjusts internal settings to ensure consistent accuracy. |

| Real-Time Diagnostics | Sensors track motor temperature, vibration, and power usage to prevent malfunctions. |

| Energy Saver Mode | Reduces energy consumption during idle or low-load conditions. |

| Error Log Memory | Records performance data for troubleshooting and maintenance scheduling. |

| Safety Interlocks | Prevents accidental startup and ensures safe operation. |

These features align with global trends in industrial automation, where data-driven control and self-correcting mechanisms are transforming how machines interact with production systems.

5. Applications of the TEK-102

The TEK-102 is highly versatile and can be adapted to a wide range of industrial applications. Its modular design and customizable attachments make it suitable for multiple operations.

| Industry | Application |

|---|---|

| Manufacturing | Component shaping, surface finishing, and assembly processes |

| Automotive | Engine part machining, body panel preparation |

| Metal Fabrication | Cutting, bending, or welding assistance |

| Aerospace | Precision machining for aluminum and titanium components |

| Construction Equipment | Assembly of structural frames and fittings |

| Energy Sector | Equipment repair and turbine component adjustment |

| Tool and Die Making | High-accuracy shaping and surface polishing |

The TEK-102’s adaptability allows it to be integrated into automated production lines, robotic systems, and CNC-controlled environments.

6. Efficiency and Performance

One of the strongest attributes of the TEK-102 is its exceptional performance under varying loads. The motor control system adjusts torque automatically depending on resistance, ensuring consistent motion even under heavy-duty tasks.

Performance Metrics

| Parameter | Value Range |

|---|---|

| Torque Output | Up to 50 Nm |

| Power Efficiency | 92–95% |

| Continuous Operation Capacity | 24 hours with thermal regulation |

| Heat Dissipation Efficiency | High (dual cooling system) |

| Operational Accuracy | ±0.05 mm tolerance |

This level of precision ensures that the TEK-102 can perform in high-demand production settings without performance degradation.

7. Advantages of the TEK-102

The TEK-102 offers a range of advantages that make it an ideal investment for industrial facilities:

- High Precision: Engineered for tasks requiring micro-level accuracy.

- Energy Efficient: Advanced inverter technology minimizes energy loss.

- Low Maintenance: Designed with self-lubricating components and sealed bearings.

- Operator Friendly: Intuitive control interface with multilingual options.

- Durability: Built for continuous operation in demanding conditions.

- Reduced Downtime: Predictive maintenance alerts prevent unplanned halts.

- Environmentally Conscious: Efficient motor and reduced emission design align with green manufacturing goals.

8. Safety and Compliance

Safety is paramount in industrial environments. The TEK-102 includes a series of built-in safety features that meet modern international standards.

| Safety Feature | Purpose |

|---|---|

| Emergency Stop Button | Instantly shuts down all functions during an emergency. |

| Thermal Overload Protection | Prevents overheating of the motor. |

| Guarding and Shields | Protect operators from rotating parts. |

| Lock-Out System | Ensures the machine cannot restart during maintenance. |

| Voltage Surge Protection | Safeguards electrical circuits from instability. |

The TEK-102 also complies with ISO and CE safety standards, ensuring reliability and operational safety for both workers and the facility.

9. Maintenance and Servicing

Proper maintenance ensures that the TEK-102 delivers peak performance for years. The machine is designed for easy access to critical components, making servicing straightforward.

Recommended Maintenance Schedule

| Maintenance Task | Frequency |

|---|---|

| Check lubrication levels | Weekly |

| Clean cooling ducts and filters | Bi-weekly |

| Inspect belts, bearings, and couplings | Monthly |

| Test control panel functions | Quarterly |

| Full diagnostic service | Annually |

Maintenance Best Practices

- Use only manufacturer-approved lubricants.

- Avoid water exposure to electrical components.

- Keep the control panel free from dust and metal shavings.

- Record all maintenance activities in a service log.

This proactive maintenance culture helps in extending lifespan and preventing operational disruptions.

10. Troubleshooting Common Issues

| Problem | Possible Cause | Solution |

|---|---|---|

| Machine not starting | Power connection fault | Check main supply and fuse |

| Overheating | Cooling system clogged | Clean air ducts and filters |

| Irregular speed | Controller calibration error | Reset to factory settings |

| Excessive vibration | Loose mounting bolts | Tighten base frame bolts |

| Low torque output | Motor overload | Adjust load or recalibrate torque setting |

By addressing minor issues early, the machine remains dependable even in long production cycles.

11. Comparison with Similar Models

| Feature | TEK-102 | Older Model (TEK-90) | Generic Equivalent |

|---|---|---|---|

| Power Output | 7.5 kW | 5.0 kW | 6.0 kW |

| Efficiency | 95% | 88% | 90% |

| Cooling Type | Dual air/oil | Single air | Air only |

| Control System | Digital Smart Interface | Analog Dial | Manual |

| Durability | 15+ years | 10 years | 8–10 years |

| Noise Level | Low | Moderate | High |

| Maintenance Cost | Low | Moderate | High |

This comparison clearly demonstrates that the TEK-102 provides superior performance, reliability, and lifespan relative to both its predecessors and generic alternatives.

12. Environmental and Economic Impact

Modern industries must balance performance with sustainability. The TEK-102 contributes to both by integrating energy-efficient motors and eco-friendly materials. The reduced power consumption results in lower operational costs and a smaller carbon footprint.

Over a 5-year period, facilities using TEK-102 machines have reported 15–20% reductions in electricity usage compared to older models. Its noise reduction and low vibration design also contribute to a healthier workplace environment, minimizing fatigue among operators and improving productivity.

13. Future-Ready Capabilities

The TEK-102 is designed to evolve with future industrial trends. It supports IoT (Internet of Things) integration, enabling remote monitoring and cloud-based diagnostics. This allows facility managers to track performance metrics and maintenance alerts in real time from any connected device.

With Industry 4.0 continuing to shape manufacturing systems, TEK-102’s compatibility with robotic arms, PLC systems, and data management software ensures it remains relevant for decades.

14. Cost and Investment Value

While the TEK-102 may represent a higher initial investment compared to entry-level machines, the return on investment (ROI) is realized through reduced downtime, lower maintenance costs, and enhanced productivity.

For example:

- Energy efficiency saves 10–15% on annual power costs.

- Low maintenance design reduces servicing expenses by 20–30%.

- High uptime ensures faster project completion and higher production yields.

Over its operational lifespan, the TEK-102 often pays for itself several times over, making it not just a purchase but a long-term industrial investment.

15. User Experience and Ergonomics

Operators report that the TEK-102 is comfortable to use, even during long shifts. Its ergonomic control layout, clear display, and reduced vibration minimize fatigue and promote accuracy. The noise-dampened motor and smooth transmission ensure a quieter working environment, which enhances focus and safety.

Additionally, the adjustable base height and intuitive control menu make it accessible for technicians of varying experience levels, reducing training time and increasing productivity.

16. Limitations and Considerations

While the TEK-102 is a powerful and versatile tool, certain considerations should be kept in mind:

- It requires three-phase power, which may not be available in small workshops.

- The weight and size demand proper installation and handling equipment.

- For specific precision micro-tasks, smaller specialized tools may still be preferable.

Despite these minor constraints, the TEK-102 remains a superior choice for medium to heavy-duty industrial operations.

17. Final Thoughts

The TEK-102 industrial machine is a symbol of how technology and engineering can converge to deliver superior performance. Its combination of durability, precision, adaptability, and efficiency makes it a cornerstone for any modern production facility. Whether implemented in automotive plants, manufacturing workshops, or fabrication lines, the TEK-102 consistently delivers results that meet and exceed professional expectations.

It stands not just as a piece of equipment but as an investment in reliability, productivity, and industrial excellence. For organizations seeking to optimize operations and future-proof their production lines, the TEK-102 remains a top-tier choice.

FAQs

1. What is the main purpose of the TEK-102 industrial machine?

The TEK-102 is designed for multi-purpose industrial applications such as fabrication, assembly, and machining. Its primary role is to provide consistent, high-precision output across different materials and workloads.

2. Is the TEK-102 energy efficient compared to older models?

Yes, it operates with up to 95% power efficiency, reducing both energy costs and environmental impact, thanks to its intelligent motor control and automatic load management.

3. Can the TEK-102 be integrated into automated production lines?

Absolutely. It’s fully compatible with Industry 4.0 standards, supporting IoT integration, robotic automation, and programmable logic controllers (PLC).

4. How often does the TEK-102 require maintenance?

Routine checks should be performed weekly, with a comprehensive diagnostic and service inspection recommended every 12 months for optimal performance.

5. What kind of training is required to operate the TEK-102?

Basic technical knowledge is sufficient to operate it safely. However, professional training is recommended to utilize all its programmable and automated features efficiently.